The photos are clickable, and clicking will take you to Flickr if you want to see the details - but they are cell phone photos and I wasn't paying much attention on the settings, so apologies in advance for the horrid glare!

Test setup for measuring tensile strength

1 metre or 50 cm of yarn, each end tied to an S-hook with a square knot. One hook was hung from a laundry hanger thingie on the balcony, and a bag was attached to the other hook by its handles. Paperback books (and for more accurate measurements, bags of instant oatmeal and individually wrapped biscuits) were added into the bag until the yarn broke.

Notes on fibre, technique and the singles

Fibre: Ronaldsay pin-drafted roving from Scottish Fibres (medium wool with some kemp and VM that I didn’t bother to remove.)

Spindle: 11g "gingerbread" top whorl spindle from Rina's Spindles.

Drafting method: short draw with twist in the drafting zone

Twist direction: Z-spun singles, all yarns S-plied, all cables re-plied Z (including the double Navajo ply).

Type: semi-woolen

Length of material available: a rough couch-length of singles (ca. 1,8m) was measured for plying all different yarns

Twist setting method: yarn was dunked in hot water and left to dry hanging freely.

Here you can see all the yarns lined up:

Results

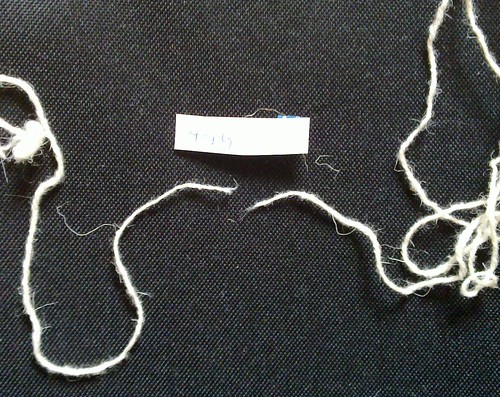

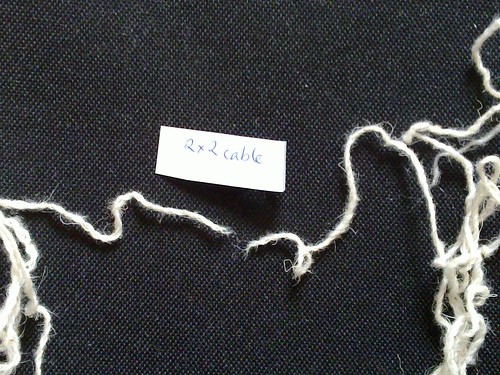

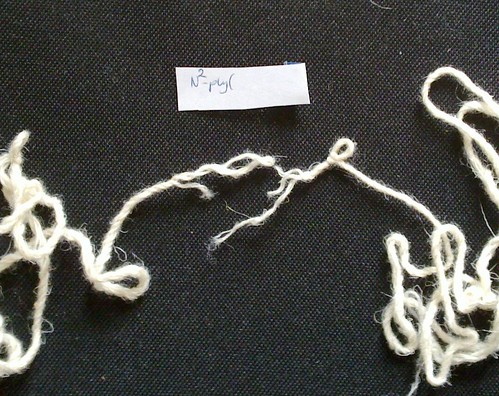

In the following there's first an image of the break, followed by the technical details of the yarn and the breaking point (all measurements are in the metric system):

Singles: ca. 38 wpi, twist angle 30-35° (1 metre sample)

Breaking point: 153g (+/-126g)

2-ply: ca. +24 wpi, plying twist angle (TA) 25° (1 metre sample)

Breaking point (BP): 556g (+/-196g)

3-ply: ca. 20 wpi, TA 20°

BP: 813g (+/-35g)

BP, second test: 838g (+/-35g)

Navajo ply: loop length: 20-30 cm, ca. 20 wpi, TA 20°

BP: 878g (+/-30g)

BP, second test: 767g (+/-35g)

4-ply: ca. 19 wpi, TA 20° (1 metre sample, stretched so much I had to move to using a shorter sample length)

BP: 1512g (+/-209g)

2x2 cable: ca. 18 wpi, TA 20°

BP: 1512g (+/-209g)

6-ply: ca. 14 wpi, TA 25°

BP: 2080g (+/-196g)

Navajo-ply, which was Navajo-plied with itself (comparable to a 9-ply): both initial and final loop length: 20-30 cm, ca. 12 wpi, TA 25°

BP: 2842g (+/- 180g)

Intermediary notes

Plying structure didn’t seem to matter very much: cabling didn’t give a dramatically greater increase in strength, and Navajo ply and traditional 3-ply were both roughly equally strong (In the first test Navajo ply survived 65g more than 3-ply and in the second, 3-ply survived 71g more, both with a tolerance of +/-35g, so the results were fairly close).

All Navajo plies showed the same distinctive pattern in breakage, as expected: in all weight tests, the break occurred at a “knot” point, usually leaving one loop in the chain intact and breaking the other one. The other structures show fraying and snapping, but it isn’t possible to predict in advance at which point of the yarn a break will occur, unlike in Navajo ply.

Stress testing continues

I still had lengths of yarn left, so I decided to perform another test - namely, how long would it take for the yarn to break, if I rubbed one point of a 30-cm long length of it against the metal radiator edge? Times varied, because I'm not a consistent machine and the yarns have weak spots, but if you are curious, here are the results of approximately how long it took to break the yarn:

Singles: 2 seconds

2-ply: 5 seconds

3-ply: 8 seconds, (second try: 23 seconds)

Navajo ply: 16 seconds, (second try: 23 seconds)

4-ply: 16 seconds

2x2 cable: 8 seconds

6-ply: 27 seconds

Double Navajo ply: 38 seconds

Still not content, I tried breaking one strand in the yarn and see how it held up to tugging (at this point, all pretense of scientific method had to be abandoned, as I don't have a device for measuring strength of pulling):

Singles: Broke easily.

2-ply: After one strand was broken, broke the same as singles yarn.

3-ply: Broke fairly easily.

Navajo ply: Broke fairly easily like the 3-ply, but if the break in the strand was close to the "knot" in the chain, the distinctive breaking pattern showed.

4-ply: Needed a little force to break.

2x2 cable: Same as 4-ply.

6-ply: Needed quite a bit of force to break.

Double Navajo ply: Needed a lot of force to break. Breaking pattern was similar to 6-ply, but if the break occurred close to a "knot" in the chain, the distinctive breaking pattern showed.

Conclusions

The single most important factor proved to be the number of plies. The strength of the yarn increased almost exponentially, when just one strand was added. The plying method was much less significant - cabled yarn and a 4-ply were roughly equal, as well as 3-ply and Navajo/chain ply, but either a 4-ply or cabled yarn was much stronger than a 3-ply or Navajo/chain ply.

The Ravelry discussion centered on the relative strength of Navajo ply. From this test I can say that at least for this fibre and these singles, 3-ply and Navajo ply were comparable. Because of the fuzziness of the fibre and the fineness of the singles, I had to check the yarn very, very closely to tell the two samples apart!

The main difference between the structures was that while the 3-ply would break at some unpredictable point wherever it was the weakest, Navajo ply would usually break at the "knot" or loop in the chain, showing the distinctive "strand and loop" pattern in one end. The exception to this was in the experiments with "sawing" the yarn through or breaking just one strand and tugging - if the break didn't occur near a knot, the yarn would behave in a similar manner to a 3-ply.

What can you conclude from all this? Surprisingly little, actually. The tests, as they stand, only comment on the suitability (or lack thereof) of using yarn for hanging things with and show that woolen spun yarn doesn't take abrasion kindly. If you change one factor (singles thickness, twist angle, drafting method, fiber preparation...) the yarn strength will change, sometimes more, sometimes less, so these results aren't the whole truth about yarn. Also, yarn in a knitted, woven or crocheted fabric will behave differently than yarn alone. Felting and level of wear and tear will also affect durability.

So don't take my word for this, but try it yourself and sample! Your yarn may yet surprise you.

(Use of these pictures (despite the less than stellar photography) and results is permitted if anyone so desires, I officially don't mind.)